Kepler Robotics K2 “Bumblebee”: A New Chapter in Humanoid Automation

The world of industrial automation has a new headline maker: the K2 “Bumblebee”. Designed and built by Kepler Robotics, this humanoid robot is entering mass production and providing a concrete demonstration of how the era of commercial humanoid machines is taking shape. Whether you refer to it by terms like kepler robot, bumblebee robotics or simply the bumblebee robot, this robot represents a leap from prototypes into real-world deployment. In the following sections, we’ll explore its main characteristics, architecture, applications, and what it means for the future of robotics and automation.

Image credit: Kepler Robotics (via PR Newswire)

Background and Manufacturer Information

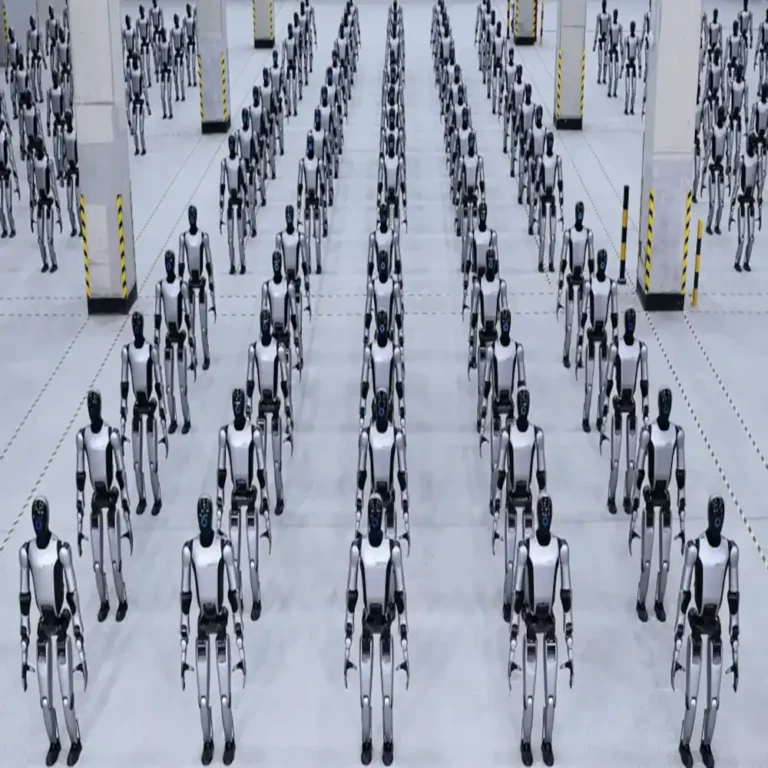

Founded in Shanghai, Kepler Robotics has positioned itself as a leader in humanoid systems tailored for industrial settings. The K2 “Bumblebee” is not just another robot; you might also see it referenced as kepler b2, kepler-b or even kepler bubble in some discussions. The entry of this robot into mass production marks a major shift: this robot is no longer a lab-only concept, but a machine built for deployment at scale. According to the official announcement, Kepler began mass production of the K2 “Bumblebee” in September 2025.

Main Characteristics and Architecture

The term kepler robot applies well here, because the K2 “Bumblebee” is built on a hybrid architecture combining humanoid mobility with industrial robustness. Standing at 175 cm tall and weighing 75 kg, it features a high-degree motion system with 52 degrees of freedom and over 80 integrated sensors.

Internally, the robot uses planetary roller screw actuators and rotary actuators in a series-parallel configuration, enabling a straight-knee biped gait and high payload capacity. This architecture is described in detail in Kepler’s gait upgrade announcement.

Some of its headline performance specs include a dual-arm payload capacity of up to 30 kg, operational endurance of up to 8 hours on a single charge (after a 1-hour recharge), and energy efficiency of around 81.3%. These figures show that the robot is designed for continuous industrial use, not just show-floor demos.

Application Scenarios in Real-world Environments

When you hear terms like bumblebee robotics or bumblbee robot in robotics media, the K2 “Bumblebee” often appears in the context of logistics, manufacturing, and service-robot applications. For example, the robot is being trialled in warehouse sorting, assembly work, and materials handling.

Some of the specific use cases include:

- Automated picking and placing in a logistics centre, with the robot navigating shelving and carrying loads up to 15 kg per arm.

- Industrial assistance tasks: supporting human workers in manufacturing by performing repetitive or physically demanding tasks, reducing fatigue and risk.

- Customer-facing service scenarios: greeting visitors, delivering items, guiding tours—thanks to its natural interaction capabilities and hybrid architecture.

These examples illustrate how this keplerth bee machine moves beyond prototypes into real operational roles.

Production, Cost and Commercialisation Strategy

One of the most important developments in robotics is when a model moves into mass manufacturing. In this case, the term kepler b2 or kepler-b becomes relevant because the K2 “Bumblebee” is positioned as the company’s flagship mass-production model. According to Kepler, shipment of the first units began in late 2025.

Pricing has also been disclosed: the base model is priced around RMB 248,000 (approximately USD 34,000) which is significantly lower than previous prototype humanoid robots costing hundreds of thousands of dollars. This relatively accessible cost is aimed at enabling real adoption in industrial environments rather than just research labs.

Design and Mobility Features

From the vantage point of a user or technical buyer, the mobility of the robot is a standout feature. The K2 “Bumblebee” walks with a straight-knee gait, adapts to complex terrain and even reacts to external disturbances, such as pushes or uneven surfaces.

Its manipulation system is equally impressive: dexterous hands with 11 degrees of freedom, force-sensing contact points and six-axis wrist sensors enable it to handle tools or objects precisely—moving beyond typical “humanoid pose” demos into real manipulation tasks.

Software Platform and Developer Ecosystem

A robot is only as useful as the ecosystem behind it. Kepler has launched an open developer platform that supports the K2 “Bumblebee”, opening up APIs, modules for vision, navigation, voice, and simulation tools. The platform allows integration with corporate systems and custom tasks.

Whether you refer to it as a kepler bubble in forums or simply “the Kepler humanoid”, this ease of development means companies won’t have to start from scratch—they can build applications on top of a robust hardware/software stack.

Considerations, Limitations and Practical Advice

While the kepler robot K2 “Bumblebee” is impressive, potential adopters should note a few caveats:

- Despite mass production, initial volumes may still be limited and lead-times significant.

- Support infrastructure, maintenance and spare parts logistics are still developing for large-scale humanoid fleets.

- Integration into existing workflows requires planning: facility layout, software onboarding and safety protocols.

From a practical advice perspective:

- Start with a pilot deployment—test the robot in one zone before scaling across your facility.

- Use the developer platform early—customise tasks and workflows rather than using out-of-box functionality only.

- Monitor metrics such as uptime, energy consumption, and task completion rate to compare robot vs human worker performance.

Considering these factors will help organisations make realistic decisions when adopting this humanoid solution rather than being swayed solely by the hype around terms like bumblebee robot lego (often used in playful comparisons) or bumblbee robot (a common misspelling online).

Future Outlook and Industry Impact

The move of the K2 “Bumblebee” into commercial deployment signals the start of a new industrial era: humanoid robots are no longer just concept machines, but products available for large-scale integration. The term kepler-b will likely become more common in industrial automation discussions as the platform gains traction.

Industries such as manufacturing, logistics, education and even hospitality may be touched by this evolution. With the integration of embodied AI, dexterous manipulation and mobility, it is plausible that by the end of the decade we will see many robots that can perform knowledge-work adjacent tasks. That is where the term kepler robot begins to represent not just hardware, but a new form of digital-physical workforce.

Conclusion and Final Thoughts

In summary, the K2 “Bumblebee” from Kepler Robotics is a genuinely significant development in the field of humanoid automation. Whether you call it the kepler robot, the bumblebee robotics platform or simply the bumblebee robot, the machine’s real-world readiness, mobility, and integration potential set it apart. For companies considering automation beyond conventional robots or arms, this platform represents one of the first viable humanoid solutions. While challenges remain, the future looks markedly different when a robot like this is ready for deployment.

Are you ready to explore how this robot could fit into your facility? Would you pilot a humanoid robot like the K2 “Bumblebee” in your warehouse or production line? Share your thoughts and questions below—let’s start the conversation.

Here are a few videos showcasing the K2 “Bumblebee” humanoid robot by Kepler Robotics:

-

Kepler Robotics K2 Bumblebee Enters Mass Production — shows the humanoid robot in its production context and some demo footage. YouTube

-

KEPLER K2 Bumblebee – a world-first live endurance challenge! — demonstrates operational endurance and agility. YouTube

-

Kepler K2 “Bumblebee” Impresses at the 2025 Zhangjiang Embodied AI Expo — showcases the robot in expo settings with public demonstrations. YouTube

FAQ

- What is the K2 “Bumblebee”?

The K2 “Bumblebee” is a humanoid robot developed by Kepler Robotics, built on a hybrid architecture and now in mass production for industrial deployment. - What tasks can it perform?

It can handle loads up to 30 kg, walk for up to 8 hours on one charge, and execute manipulation tasks with millimeter precision in industrial environments. - What industries are targeted?

Logistics, manufacturing, R&D, education and service roles are core targets for deployment. - How much does it cost?

The base unit is priced around RMB 248,000 (≈US$ 34,000) for commercial buyers. - What makes it different from other robots?

Its hybrid actuator architecture, high mobility, dexterous manipulation and mass-production readiness distinguish it from many other humanoid robots still in lab-mode.