China Deploys ‘Army’ of Humanoid Robots for 24/7 Factory Labor

China Deploys ‘Army’ of Humanoid Robots for 24/7 Factory Labor

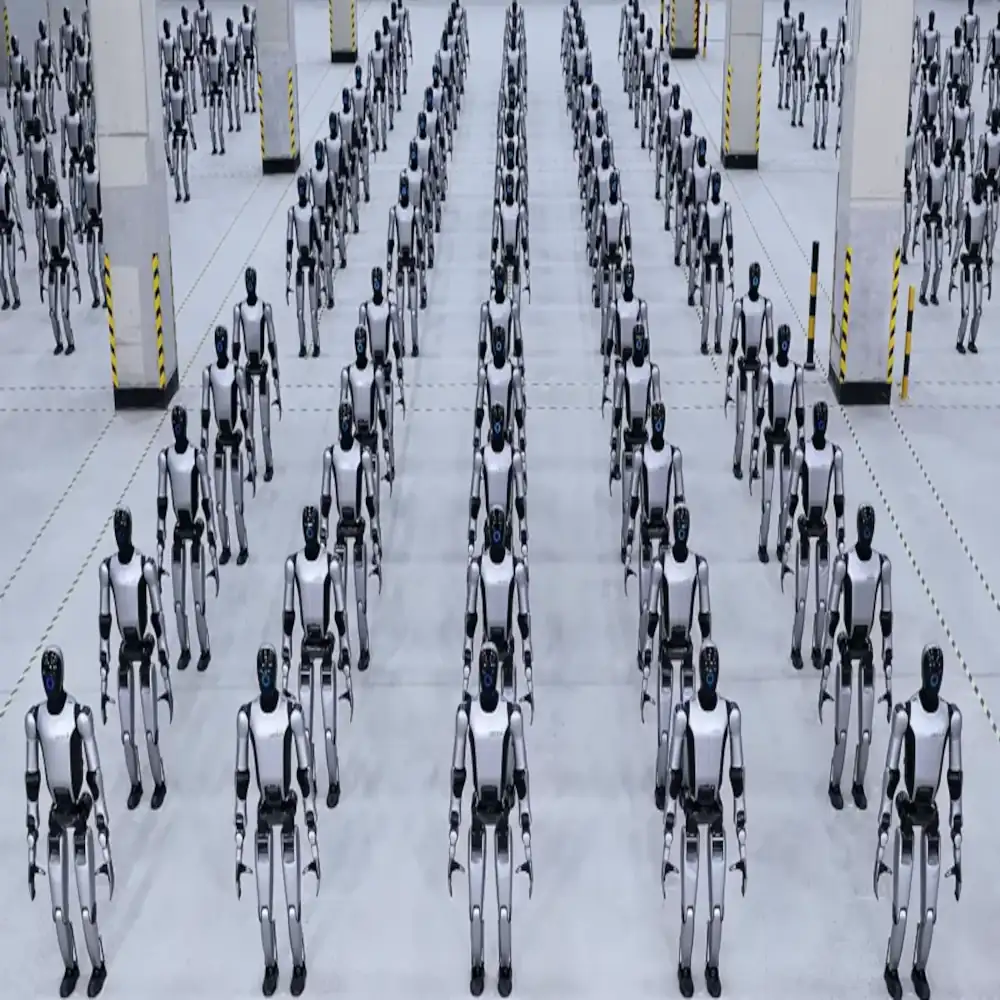

Imagine a factory that never sleeps. Not just a place with bright lights and a night shift, but a facility where work continues with relentless precision through the darkest hours, completely autonomously. This vision is now a reality in China, where the deployment of an “army” of humanoid robots is fundamentally reshaping manufacturing. Spearheaded by companies like UBTECH, this isn’t a small pilot program; it’s a full-scale industrial revolution powered by advanced robotics. These aren’t the single-purpose robotic arms you’re used to seeing. We’re talking about bipedal, dexterous humanoids designed to work 24/7, performing complex tasks that were once the sole domain of human workers. This strategic move addresses critical challenges like labor shortages and the intense demand for faster production, marking a pivotal moment for global supply chains and the future of work itself.

The scale and ambition of this initiative is what truly sets it apart. We’ve moved beyond the concept phase and into an era of mass deployment. The recent news of UBTECH delivering its humanoids to factories isn’t a one-off event; it’s a signal that the technology has matured to a point of commercial viability and scalability. These humanoids are being integrated directly into existing assembly lines, working on everything from consumer electronics to automotive components. For business leaders and industry watchers worldwide, this is a clear indicator that the transition to a hybrid human-robot workforce is accelerating faster than many anticipated. The conversation is no longer about *if* this will become the standard, but about how quickly other nations and corporations will need to adapt to keep pace.

Image Credit: UBTECH Robotics

The Technology Behind the Humanoid Workforce

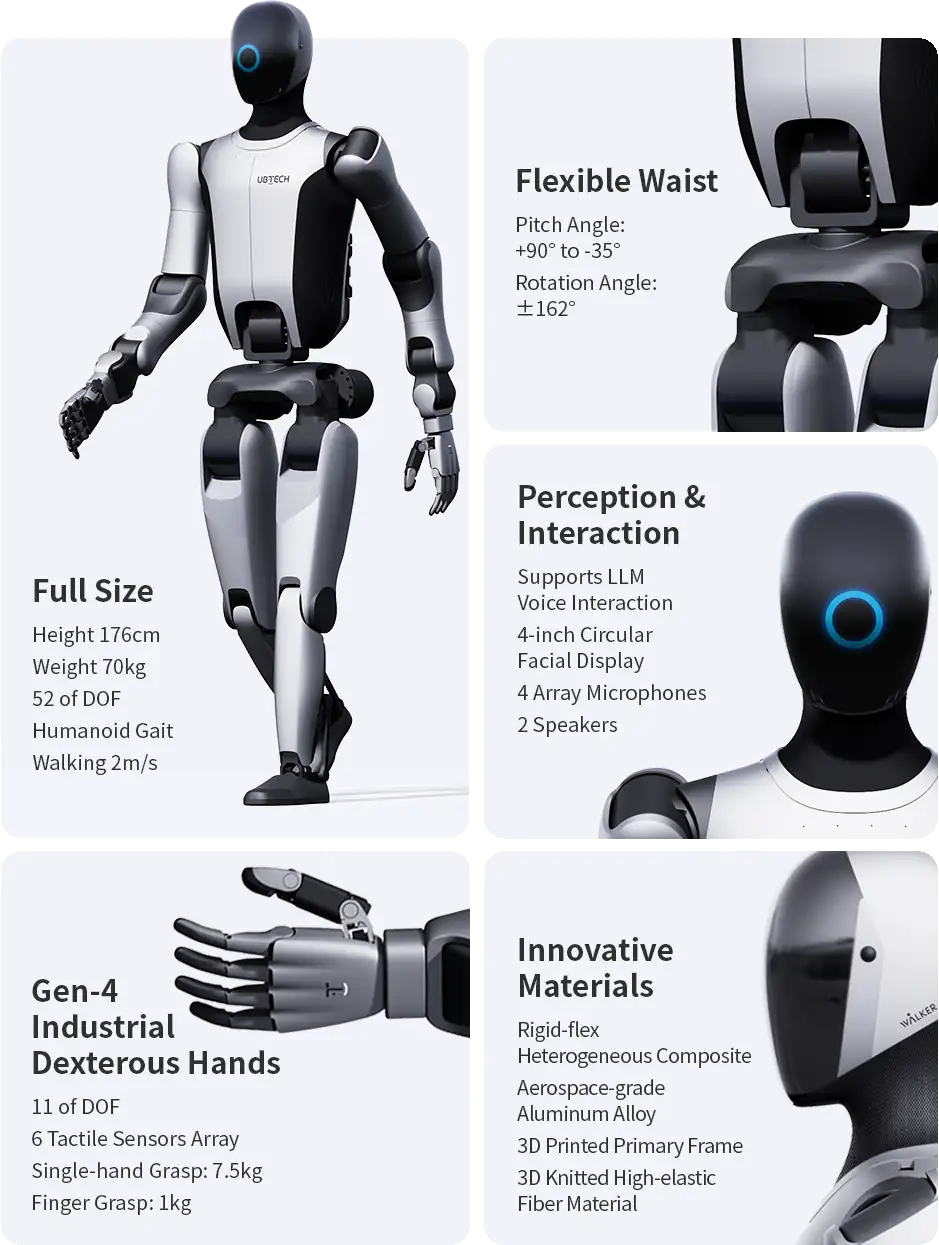

So, what makes these new humanoids from companies like UBTECH so different? The answer lies in a convergence of advanced mechanics, sensors, and artificial intelligence. The UBTECH Walker S2, for instance, is a testament to this progress. It stands on two legs, navigates complex environments built for humans, and uses its multi-jointed hands to perform delicate manipulation tasks. This bipedal design is a game-changer because it eliminates the need to completely redesign factory floors. Unlike traditional robots that are bolted down, these humanoids can walk to different stations, climb stairs, and adapt to a dynamic workspace. Their ability to handle tools and components with a human-like grip allows them to slot into existing workflows with minimal disruption, a key factor for their rapid adoption.

The intelligence driving these UBTECH humanoids is just as impressive as their physical form. They are powered by sophisticated AI that enables real-time perception and decision-making. Through a combination of computer vision, force feedback sensors, and deep learning algorithms, these robots can perform tasks with a high degree of accuracy. They can be trained using imitation learning, where they watch a human perform a task and then replicate the movements, refining their technique over time. This level of adaptability is crucial for modern manufacturing, which often requires frequent changes to product designs. The versatility of these humanoids means they can be reassigned from one task to another, making them a flexible asset rather than a fixed piece of machinery. This represents a significant leap from the rigid automation of the past.

Mass Production and Real-World Applications

The most telling sign of this technology’s maturity is its transition into mass production and deployment. The recent news highlights that these humanoids are not prototypes; they are commercially available products being sold and delivered in large numbers to factories. This shift from the lab to the factory floor is monumental. Companies are making substantial investments in fleets of these robots, confident in their ability to deliver a return on investment through increased uptime and consistency. The era of humanoids as a niche, experimental technology is over. They are now a tangible, scalable solution being deployed to solve real-world industrial problems today, with UBTECH leading the charge in making these advanced humanoids a common sight on production lines.

In practical terms, what are these humanoids actually doing? Their applications are surprisingly diverse. In electronics manufacturing, they are adept at tasks like precision soldering, component placement, and quality inspection using their advanced vision systems. In logistics and warehousing, they can be used for picking and packing, moving boxes, and managing inventory. The key advantage across all these applications is their ability to work around the clock without fatigue. A single humanoid can effectively cover multiple shifts, performing repetitive and physically demanding tasks with unwavering precision. This not only boosts overall output but also frees up human workers to focus on more complex, cognitive, and supervisory roles that require problem-solving and creativity.

- High-Precision Assembly: Installing delicate components in smartphones and laptops with sub-millimeter accuracy.

- Quality Control: Using high-resolution cameras to identify microscopic defects that the human eye might miss.

- Material Handling: Transporting raw materials and finished goods between different stations on the factory floor.

The Economic Drivers and Global Impact

The push towards a robotic workforce is driven by a powerful economic logic. For China, and increasingly for other manufacturing hubs, the traditional model of relying on a vast, low-cost labor force is becoming unsustainable. Demographic shifts, with an aging population and a shrinking working-age cohort, are creating a pressing need for automation. Humanoids offer a solution to this demographic challenge. From a pure cost perspective, while the initial capital outlay is significant, the long-term operational savings are substantial. These robots don’t require salaries, benefits, or rest breaks, and they maintain a consistent level of quality and speed 24 hours a day, leading to a compelling return on investment for factory owners.

This trend has profound implications for the global manufacturing landscape. For decades, the flow of production was dictated by labor costs, leading to widespread offshoring. The proliferation of humanoid robots could fundamentally alter this calculus. If the cost of labor becomes less of a factor due to automation, other considerations like proximity to key markets, supply chain resilience, and intellectual property protection may become more important. This could encourage a trend of “reshoring” or “nearshoring,” where production is brought closer to the end consumer. The competitive advantage may soon shift from which country has the cheapest labor to which country has the most advanced and integrated automated infrastructure, a shift that could redistribute global manufacturing power.

Navigating the Human Element in an Automated Future

Of course, the rise of a robotic army in factories inevitably brings questions about the human workforce. The common fear is one of mass job displacement. While it’s true that certain manual, repetitive roles are likely to be automated, the complete picture is more nuanced. The introduction of humanoids doesn’t just eliminate jobs; it transforms them. There is a growing demand for a new class of skilled workers: robot operators, maintenance technicians, AI supervisors, and data analysts who can interpret the vast amounts of information these systems generate. The challenge, therefore, is not a net loss of employment, but a critical skills gap that needs to be addressed through comprehensive retraining and education initiatives.

The future of manufacturing will likely be one of collaboration, not replacement. The most efficient factories will be those that successfully leverage the unique strengths of both humans and robots. Humanoids will handle the predictable, physically taxing, and repetitive tasks, while human workers will focus on areas where they excel: strategic oversight, complex problem-solving, creative design, and managing the robotic systems themselves. This symbiotic relationship can lead to a safer and more engaging work environment, where human potential is amplified by technology rather than suppressed by it. The successful integration of these UBTECH humanoids and others like them will depend as much on our ability to adapt our workforce as it does on the technology itself.

Image Credit: UBTECH Robotics

Preparing for the Inevitable Shift in Manufacturing

For businesses and individuals, the message is clear: the automation of physical labor is accelerating, and preparation is key. Company leaders should be actively auditing their operational processes to identify which tasks are ripe for automation. Investing in these technologies now can provide a significant competitive advantage in terms of efficiency, cost control, and production scalability. For investors, the robotics and AI sectors represent a high-growth frontier, with companies like UBTECH at the forefront of a major industrial transformation. The businesses that thrive will be those that view this not as a threat, but as an opportunity to reinvent their operations for the 21st century.

On a personal level, the rise of the humanoids underscores the increasing value of uniquely human skills. As routine tasks become automated, attributes like critical thinking, creativity, emotional intelligence, and complex communication will become the most valuable currencies in the job market. A commitment to lifelong learning and adaptability is no longer a luxury; it’s a necessity. The transition may be disruptive, but it also opens up new possibilities for more meaningful and intellectually stimulating work. The factories of the future, populated by both humans and humanoids, promise a new chapter in industrial history—one defined by unprecedented productivity and human ingenuity working in concert.

Your Thoughts on the Robotic Revolution

The deployment of humanoid robots on this scale is a topic that affects us all, from business owners and workers to consumers. What is your perspective on this rapid shift? Do you see the integration of humanoids like those from UBTECH as a net positive for the global economy? If you work in manufacturing, how is your company preparing for these changes? Share your experiences, concerns, and predictions in the comments below. Let’s have a conversation about the future we’re building together.

Frequently Asked Questions

- Are UBTECH humanoids like the Walker S2 truly autonomous?

They operate with a high degree of autonomy for specific tasks but work within a predefined framework and under human supervision for overall coordination and complex problem-solving. - What is the main advantage of a humanoid form over other robot types?

The primary advantage is their ability to work in environments designed for humans, using the same tools and navigating the same spaces without requiring costly factory redesigns. - How do these robots impact product quality?

They significantly improve consistency and reduce errors caused by fatigue, leading to higher overall product quality and fewer defects. - Is this technology accessible to small and medium-sized businesses?

Currently, the cost is a barrier for smaller players, but as the technology scales and becomes more common, prices are expected to fall, making it more accessible, similar to the evolution of other technologies.

Sources

- https://www.ubtrobot.com

- https://noticias.uol.com.br/internacional/ultimas-noticias/2025/11/16/china-entrega-exercito-de-robos-humanoides-para-trabalho-24h-em-fabricas.htm

Author comments

Our website is for informational purposes only. We are lovers and enthusiasts of the latest and most innovative technologies. We only comment on and share what is happening in the world of Humanoids here in this section, and of course we always mention the sources or sources of the news and their origins so that you can delve deeper into the subject on your own.

HJunior

I am HJunior, SEO Writer, Copywriter, and enthusiastic and passionate about technology, future blockchain programmer.

Facebook

Twitter

LinkedIn

Instagram

Youtube

Edit Template